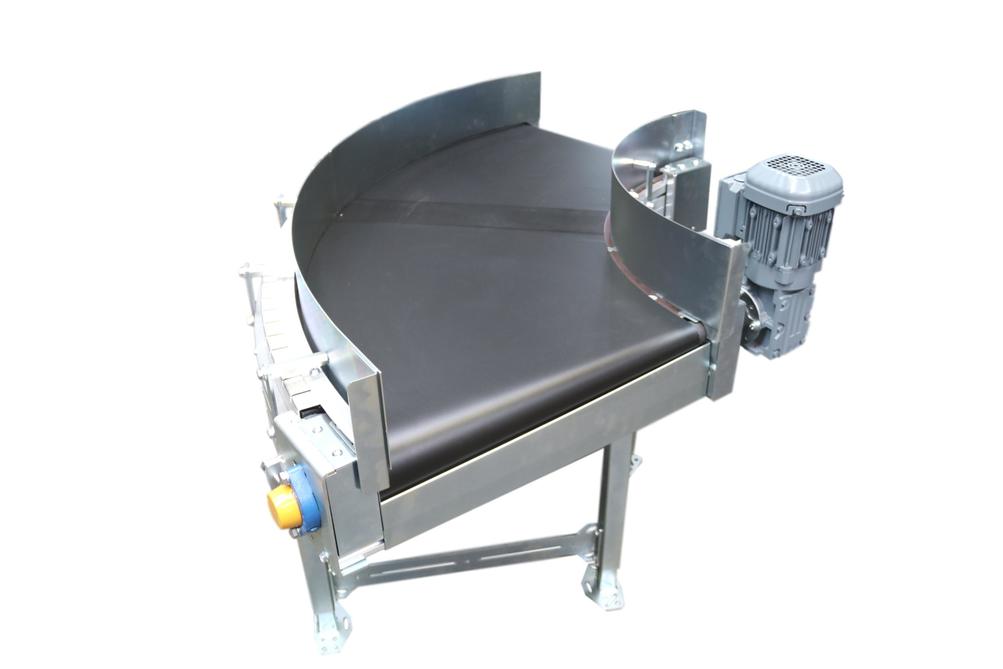

Belt Conveyors

Belt Conveyors - Standard Product Range

BELT CONVEYOR MANUFACTURES

We are a belt conveyor manufacturing company, producing our own line of new belt conveyors and belt conveyor systems, from our site in Telford Shropshire.

We have a custom-built manufacturing facility, where we are in control of our own conveyor belt manufacturing, design, steel processing, finishing and assembling of conveyors from start to finish

All our conveyor frame profiles, drive and tail rollers, welding and fabrications are carried out at our Telford facility, so we can closely monitor the manufacturing of your belt conveyor from start to finish.

HOW DOES A BELT CONVEYOR WORK?

A Basic flat belt conveyor works by incorporating two rollers; One being an idler pulley and another being a powered pulley.

These rollers are then set into a solid frame typically made from steel, stainless steel, or aluminum profile.

Manufacturers will fold this frame using a brake press, as a solid C section with a reverse bend, or Create two parallel Z sections to be joined together.

When using a Z Section the two frames will be joined together using a cross brace. Cross braces are typically welded bars and/or bolted cross members.

The Slider bed of the conveyor will usually be decided based on the application of the conveyor. In warehousing, slider beds will usually be made up either using rollers or folded steel sections called bedpans/trays or bed sections.

The advantage of using bed rollers over pans would be that the load over the drive will be decreased dramatically, as the friction derived from the belt is far less.

This advantage is particularly important when considering the drive size required to pull the necessary force to be placed on the belt.

And can also be an advantage when considering the total power consumption of a belt conveyor system.

Drive Locations can also play an important part in belt conveyors. Typically a drive would sit at the end of the conveyor to pull the belt in the correct direction of travel.

When belt conveyors are required to be functional in forward and reverse directions or considering a belt length over 10m, it will be fairly common practice to expect these conveyors to have a centrally located drive unit.