KCB-113

KCB 113 Belt Conveyors

Light to Medium Duty belt conveyors with up to 200KGS capacity.

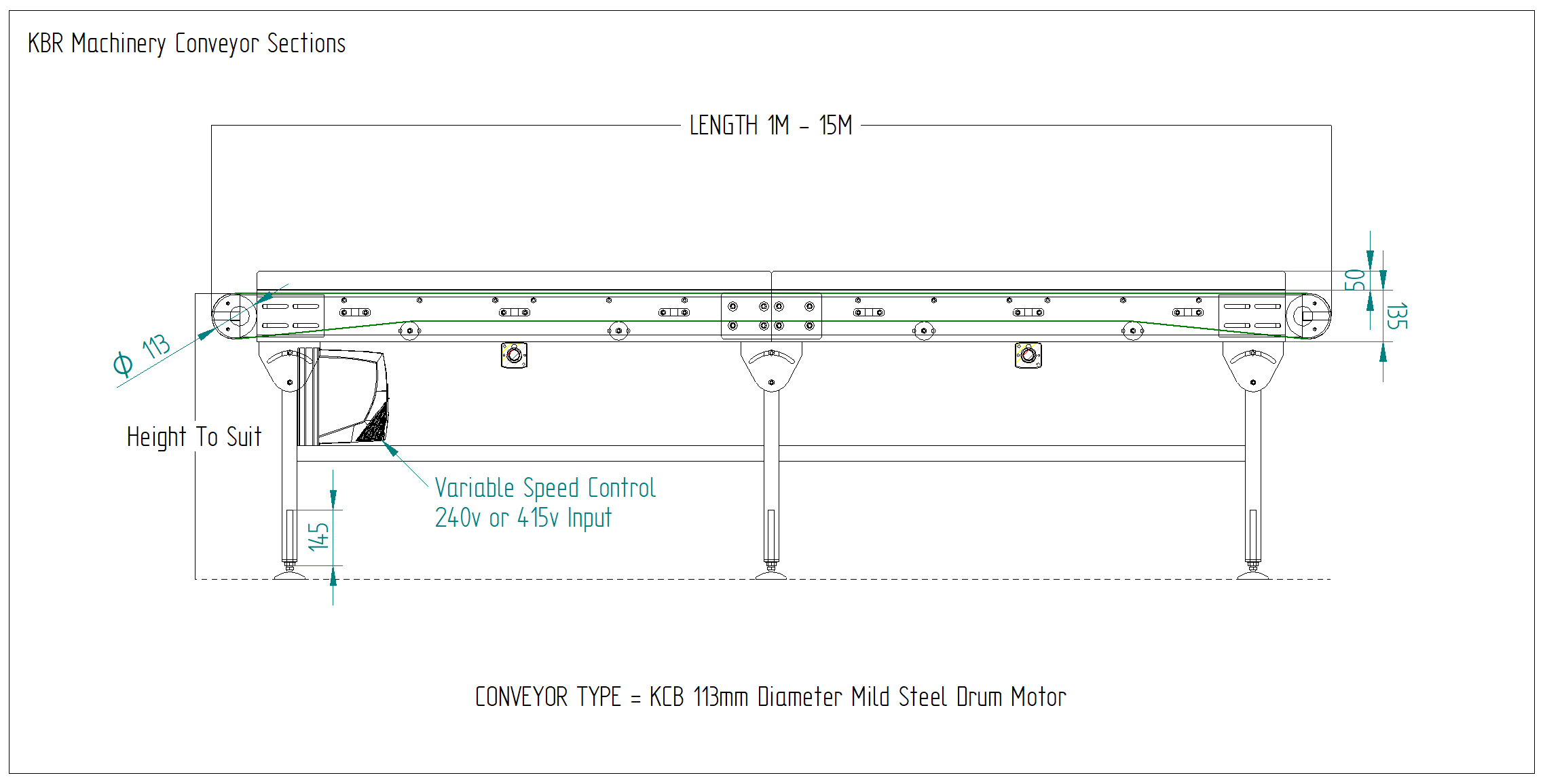

113mm Ø Drive & Tail Rollers - Steel Geared Drum Motor Units

CONVEYOR OVERVIEW

The KCB 113 belt conveyor is one of our most popular conveyors, down to the versatility this machine can offer to a wide range of industries.

This robust, high-quality belt conveyor is ideal for medium-duty conveyor applications, up to 200kgs capacity with specific drives.

An ever-popular choice for material handling solutions, down to the key running features including tracking guidance, superior quality British manufacturing, and 12-Month Manufactures warranty without compromising on price.

In addition to the packed-in features and accessories available, the KCB 113 conveyor is manufactured from high-quality cold-rolled CR4 grade 2.5mm mild steel. Conveyor side sections are CNC cut and folded to form a strong durable side section, in addition to a 4 side semi-suspended support pan, allowing our twin belt tracking guidance system.

Offering a solid 135mm deep side section and a sturdy supporting base, the KCB 113 medium-duty belt conveyor is a durable conveyor, meeting the high demands of all KBR Conveyor Sections manufactured range.

The KCB 113 medium-duty belt conveyor, therefore, remains an ever-popular, solid, robust and ultra-reliable belt conveyor system.

The KCB 113 belt conveyors can be supplied in 3 standard colours, RAL5002 Ultramarine Blue, RAL 9010 Pure White, RAL 9005 Jet Black. Custom powder coated colours are available. Together with 304 stainless sections manufactured for food conveyor applications.

CUSTOMER SUPPORT

Our conveyors are supplied as standard with a 12 Month Manufacturers Warranty.

Conveyors can be supplied pre-built up to 5m or supplied in a kit form with a pre-vulcanized belt and comprehensive instructions provided.

Some require minimal assembly, and some a little more than the simple assembly. If you don’t think you could manage, or simply want the assurance of a professional installation and demonstration, we can offer an installation service for an extra cost.

To find out how much assembly is required on your conveyor, please contact us.