Incline Floor Conveyor Mezzanine Conveyors

Conveyor Overview

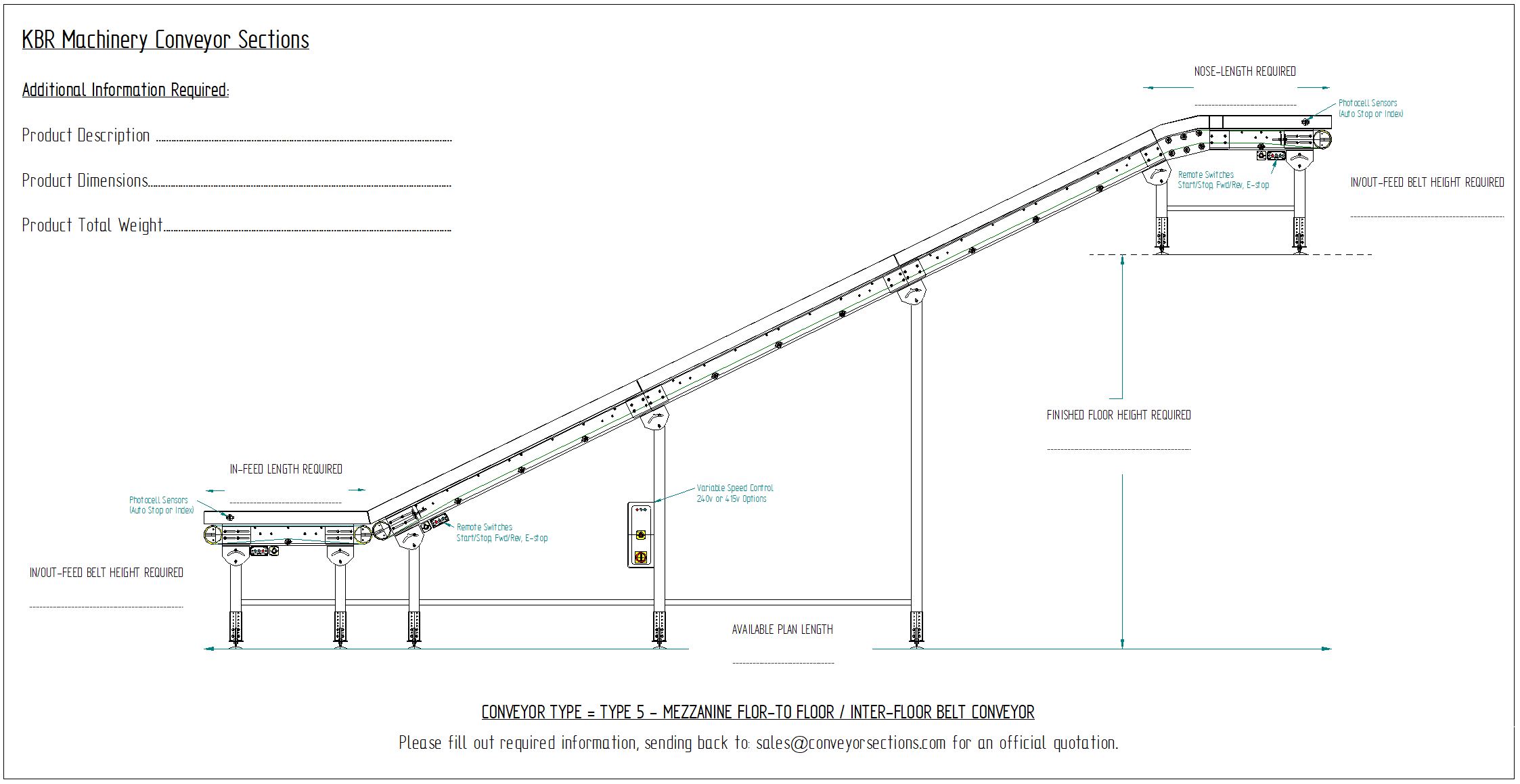

Inclined mezzanine floor conveyors offering bi-directional conveying for inter-floor transfer of goods.

Ideal for usage within warehouse & distribution aiding goods inwards-outwards scenarios, saving time, money, and most importantly, the health and safety of operatives by reducing strains, pains, and injury by improving the manual handling of cartons and totes.

How Do Floor to floor conveyors work?

The movement of unit loads between different floor levels is a problem amongst most companies.

A typical solution may be to add a forklift-gate to the front edge of the floor, to be loaded and unloaded by a counterbalance reach truck. - This is not always viable and comes with its own set of problems, including increased traffic, equipment hire, maintenance, then the requirement for additional staff training/licensing, etc the list goes on.

There is another option............

Floor to Floor conveyors as the name suggests, provide a complete solution to inter-floor connectivity in the form of handling regular units of products in warehouse environments.

Mezzanine conveyor belts offer a safe, permanent point of loading, which can be used by any warehouse operative to safely and effectively load and unload stock between floors. This comes without the need for counterbalance reach trucks or staff members negotiating heavy loads up and down staircases.

By utilizing the same principals of our other horizontal belt conveyors, we are able to utilize the inclined floor conveyor to form angles of anywhere up to 25 degrees, with floor heights up to 6m finished floor level.

Conveyors feature bi-directional controls, enabling the user to begin the cycle of goods traveling along the moving belt until they reach the required floor level.

Once the level has been reached, a PEC or Photo Electric Cell sensor will pause the conveyor, allowing for the operative to unload the conveyor when safe and suitable to do so.

When the operator removes the item on the conveyor, the belt will resume travel until the next item activates the PEC, thus stopping the belt - This process is called 'Indexing'.

Conveyor indexing is a commonplace way to run single standing mezzanine floor conveyors, allowing single persons or two-man teams to safely and effectively move stock between two levels.

Interfloor conveyor advantages

Mezzanine floor conveyors provide a reliable, cost-effective solution to covey materials as part of the production, warehousing, and storage of many types.

Installations of mezzanine floors create further production space and storage facilities for further expansion. The introduction of verticle floor to floor conveyors aid and facilitate the usage of these key areas, in a safe and controlled manner.

Incline floor elevators are a far more cost-effective alternative to rival product options such as Spiral Conveyors / Chutes and Verticle Conveyor lifts. Furthermore, they are more mechanically robust, tending to be less problematic. Spiral elevators and verticle conveyor lifts feature many complex or difficult to source parts, which makes ongoing maintenance expenses.

Build Quality at a Glance

Specifying the correct conveyor is an important task. Our Inclined interfloor conveyors are manufactured in three frame types, dependant on floor height either 135, 162 & 192mm frame profiles, with light or heavy-duty build quality for any application.

Conveyors are fitted as standard with Textured 2 ply PVC Grip belting, with fully vulcanized joins, with the addition of additional features such as our twin tracking guides, 100mm side guarding, under guarding and 'pop-out' rollers.

Many Drive configurations are available including shaft-mounted motors, motorized drum motors, and centrally located underslung drives as standard.

Our machines use quality British manufacturing techniques together, with fully folded, durable, steel profile side sections, with packed in features like our twin belt tracking guidance system across the range.

The KCB belt conveyors can be supplied in 3 standard colors, RAL5002 Ultramarine Blue, RAL 9010 Pure White, RAL 9005 Jet Black. Custom powder coated colors are available.

Industries & Applications

Typical industries include, but not limited to, Pick and Pack/Place Operations, Warehouse, Distribution, Logistics, and E-commerce,

These heavy-duty Incline elevators offer a superb handling capacity, up to 500kgs with specific drives. Furthermore, our versatile design approach offers many customizable features including, side guards, adjustable guide rails, customized belting, under-guarding, and a range of supporting structure dependant on conveyor heights.

For increased accumulation of products, our Range of Gravity Roller Conveyors enable a stock buffer, this increases the amount of time the conveyor can run until the PEC sensor will activate.

Tailor-made custom electrical control options are available in addition to the range of our standard control.

summary

Incline floor conveyors are a purposeful advance to any company with the requirement to handle goods on single or multiple levels.

Offering key benefits to the health and safety of staff, increasing work output efficiency and productivity while remaining a sensible and affordable capital investment.

CUSTOMER SUPPORT

Our conveyors are supplied as standard with a 12 Month Manufacturers Warranty.

Conveyors can be supplied pre-built in a kit form with a pre-vulcanized belt and comprehensive instructions provided.

Some require minimal assembly, and some a little more than the simple assembly. If you don’t think you could manage, or simply want the assurance of a professional installation and demonstration, we can offer an installation service for an extra cost.

To find out how much assembly is required on your conveyor, please contact us.