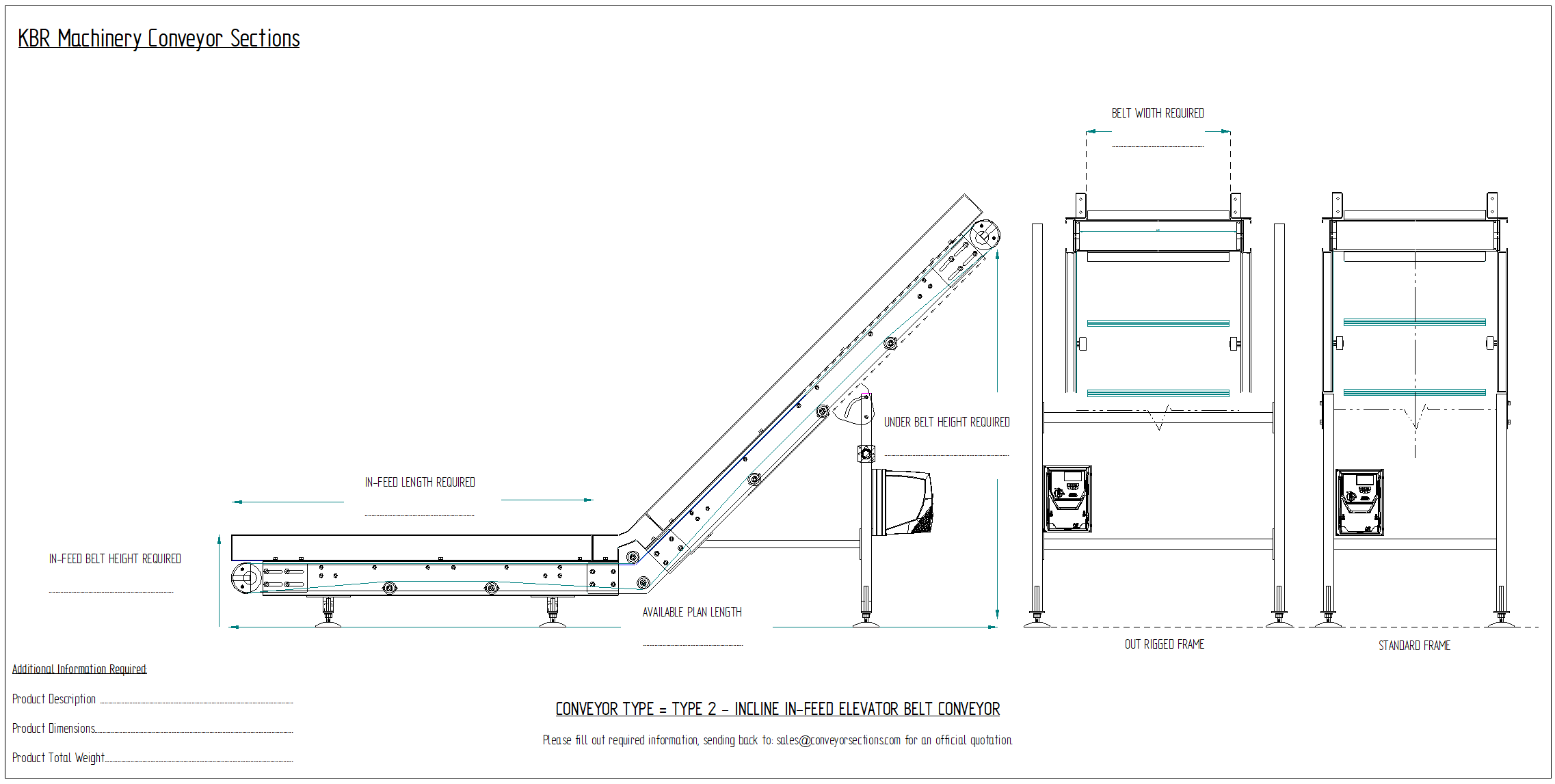

Incline In-Feed Belt Conveyor

Conveyor Overview

Type 2 Incline in-feed conveyors are manufactured for applications requiring a flat horizontal section for parts to initially fall onto, prior to being elevated to a final position.

The conveyors are the perfect addition to CNC machine out-feeds for example in plastics manufacturing, to remove parts, bringing them to operator level.

Build Quality at a Glance

Conveyors are manufactured using 101, 135, 162 & 192mm frame profiles, with light or heavy-duty build quality for any application.

Our machines us quality British manufacturing techniques together, with fully folded, durable, steel profile side sections, with packed in features like our twin belt tracking guidance system across the range.

The KCB belt conveyors can be supplied in 3 standard colors, RAL5002 Ultramarine Blue, RAL 9010 Pure White, RAL 9005 Jet Black. Custom powder coated colors are available.

Industries & Applications

Typical industries include, but not limited to, Plastics Manufacturing & Extrusion, Pharmaceutical Conveyors, Food Waste, Automotive Conveyors, Pressings Conveyors with applications such as Hopper Loading, Bag Filling Lines, Scrap, or Waste Bins, Baskets & Cages, bulk bagging.

These heavy-duty Incline elevators offer a superb handling capacity, up to 500kgs with specific drives. Furthermore, our versatile design approach offers many customizable features including, side guards, hopper systems, customized belting, sidewalls, spill edges, backplates, tapered in-feed guards, adjustable side rails in addition to a full range of cleats and flights.

Tailor-made custom electrical control options are available in addition to the range of our standard control.

summary

In-feed Inclines have a distinct advantage over our Type 1 Nose-Over conveyors whereby providing a positive and stable area for parts to be dropped and positioned prior to elevation.

Furthermore, advances can be gained to the in-feed, through additional components such as hoppers, back-plates, and flared side guard kits, therefore, remain a fully customizable, solid, robust, and ultra-reliable belt conveyor system.

Supporting structures for the out-feed-end of the conveyor can be inset to aid filling of bags and bins.

CUSTOMER SUPPORT

Our conveyors are supplied as standard with a 12 Month Manufacturers Warranty.

Conveyors can be supplied pre-built up to 3m (Plan Length) / 2.5m (Out-Feed Height) or supplied in a kit form with a pre-vulcanized belt and comprehensive instructions provided.

Some require minimal assembly, and some a little more than the simple assembly. If you don’t think you could manage, or simply want the assurance of a professional installation and demonstration, we can offer an installation service for an extra cost.

To find out how much assembly is required on your conveyor, please contact us.